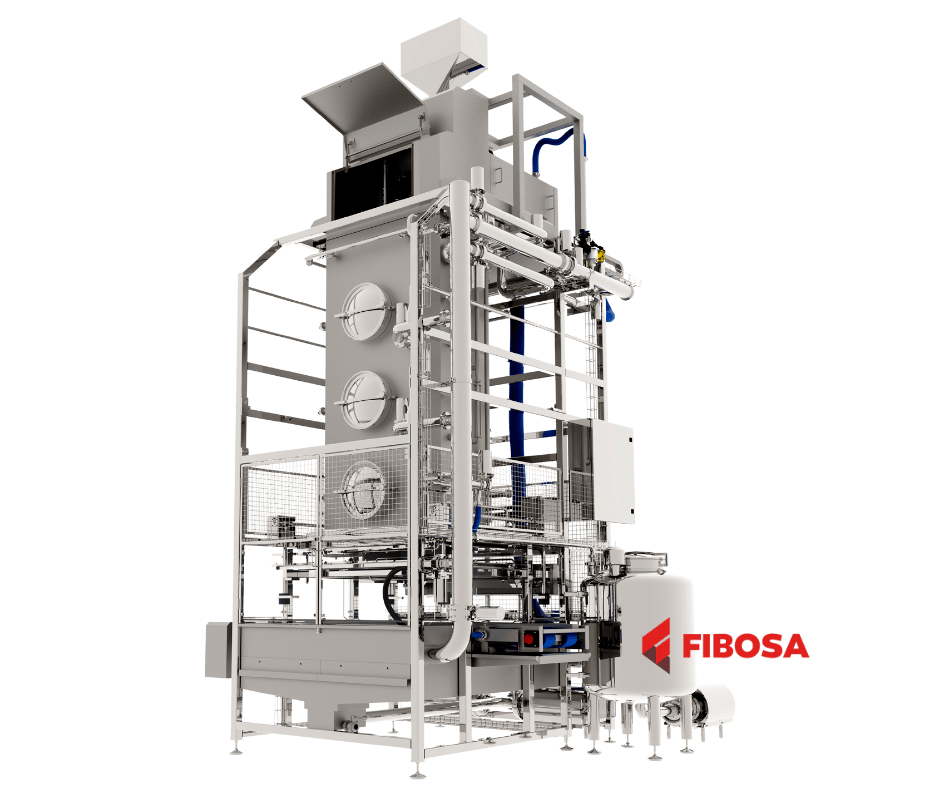

Fibosa cheese dosing machines

Fibosa’s dosing machines for Pecorino Siciliano cheese and other Southern Italian specialties are equipped with a dosing device for spices and other curd ingredients. The ingredient dosing system is located at the top of the curd dispensing spout of the cheese dosing-molding machine. This assembly, mounted together with an agitator, helps to mix the products uniformly. It is composed of a hopper that receives the ingredients and a drum that doses the desired amount to be added to the curd.

Sicilian mixed cheese is a traditional specialty of Sicily, similar to Sicilian Pecorino, Canestrato and other varieties of cheese from southern Italy.

Origin: Sicily, Italy

Texture: Semi-hard to hard, depending on ripening time.

Types of cheese: with pistachio, olives, pepper, arugula, truffle or other ingredients or spices.

Auxiliary tank for recovery of clean serum

The auxiliary whey tank has the function of collecting all the clean whey coming from the delivery spout before the addition of ingredients to the curd. This whey is recovered by means of an impulsion pump to be used in other treatment processes. In this way, a high percentage of the sweet, clean whey is recovered, without being affected by the addition of additional ingredients.

Features and benefits

This machine unifies in a single unit the systems for the production of soft, semi-hard and hard cheeses. The equipment saves space and handling time, increases flexibility and production capacity, and achieves optimum homogeneity of the final product.

System components

The machine is composed of three independent main modules for the different phases of processing, molding and dosing:

- Upper curd distribution assembly: Incorporates filtering and agitation mechanisms for the draining process.

- Intermediate module or cassette: It gathers a set of microperforated columns of exclusive design and independent whey levels that achieve a draining and pre-pressing adapted to each type of product.

- Lower module: Composed of reinforced and easily interchangeable, automatically adjustable shapers to produce cheeses of different heights. Includes a set of high precision cutting blades.

Technology and automation

The cheese dosing machines incorporate a conveyor assembly and allow the control and regulation of parameters and processes by means of a programmable automaton and a touch screen. They are adapted for the CIP cleaning system.

Optionally, it can be complemented with a washing cabinet for the set of columns and accessories, a hoist for the extraction of the set of columns and an access platform.

This integrated approach ensures efficiency in cheese production, improving the quality and homogeneity of the final product.