What is a SCADA system?

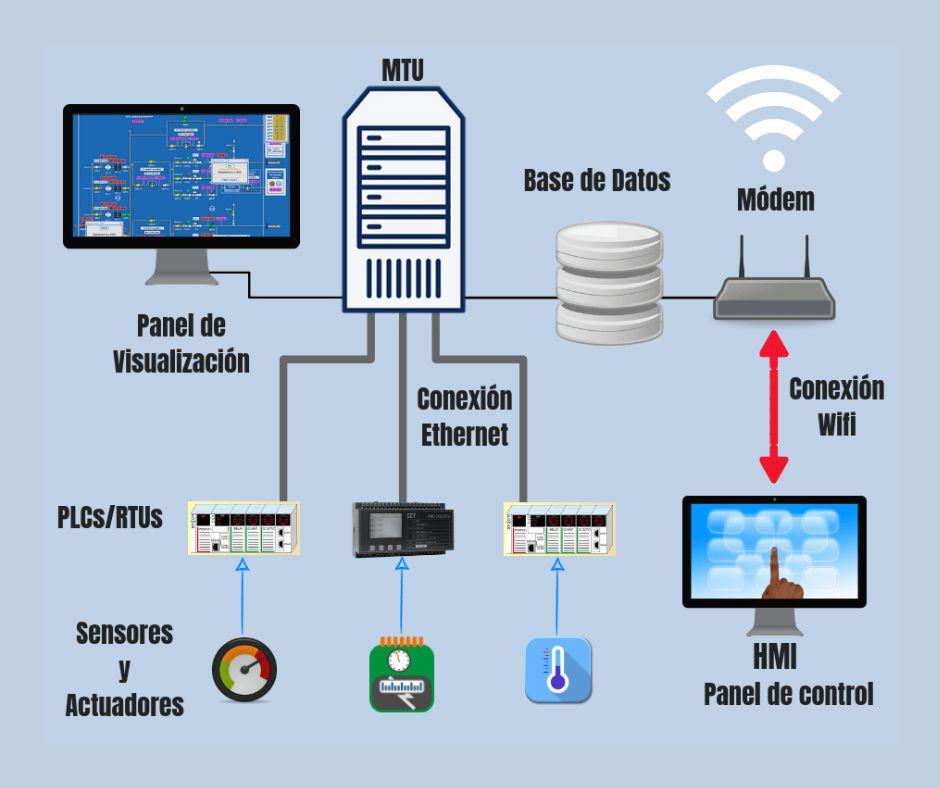

A SCADA centralized control system is an industrial automation and control solution that monitors, collects and analyzes data remotely using specialized software. SCADA systems are in charge of controlling production activities interconnected with PLCs and RTUs, maintaining process efficiency, processing data in real time and communicating any system problems.

What are they for?

SCADA systems are used to control industrial processes both locally and remotely. They monitor and process data in real time, interacting with devices such as sensors and valves. In addition, they record production process events, create alarm panels and manage maintenance, thus improving quality control through data collection.

How does it work?

PLCs and RTUs communicate with instruments such as HMIs, sensors and end devices. The collected information is routed to computers with SCADA software for processing, distribution and display. Operators analyze this data and make decisions based on the information provided by the system. In addition, the system quickly reports any problems so that corrective action can be taken immediately.

Importance of SCADA systems

SCADA systems automate and optimize responses to measured conditions, eliminating human error and automating routine tasks. This increases productivity and improves real-time fault management. In addition, they are capable of monitoring and controlling large geographical areas, which is crucial for the profitability of industrial operations.

SCADA centralized control systems in our FIBOSA plants

SCADA systems are used in medium to large-scale dairies to maintain efficiency and reduce downtime. Customers have full control of the plant through touch screens located in different machines and manufacturing areas. This automation system records all production data in real time, and allows configuring recipes for the different formats or types of cheese to be produced. In addition, it also records possible stoppages and the reasons why they have occurred, allowing the line’s performance to be monitored and enhanced at all times.