The process of making fresh cheese is essential to obtain a high quality product that meets the expectations of flavor, texture and freshness sought by consumers. This process, which combines tradition and technology, ensures that each stage of production is carried out under strict hygiene and quality controls. From milk pasteurization to final packaging, each step is designed to preserve the natural properties of fresh cheese and guarantee a healthy and delicious food.

Stages in the process of making fresh cheese

Milk reception and pretreatment: Raw milk is subjected to quality tests and pre-hygienization, if necessary, before being stored in refrigerated tanks. This step guarantees the purity and freshness of the raw material to obtain a quality final product.

2. Pasteurization: Milk is heated to controlled temperatures to eliminate pathogenic microorganisms, ensuring food safety of the final product.

3. Coagulation in curdling vats: Once pasteurized, it is transferred to curdling vats, such as FIBOSA’s curdling vats, where lactic cultures and rennet are added to induce curd formation. These vats are designed to mix the curd homogeneously, obtaining a regular grain and minimizing wastage.

4. Cutting and draining: The curd formed is cut into uniform fragments to facilitate the expulsion of the whey until the desired texture of fresh cheese is achieved.

5. Molding and dosing: We transfer the cut curd to molds, using equipment such as FIBOSA’s fresh cheese dosing machine, which adapts to different formats and guarantees a homogeneous production.

6. Pressing: Although fresh cheese does not require intense pressing, light pressure can be applied mechanically to remove excess residual whey and shape the cheese.

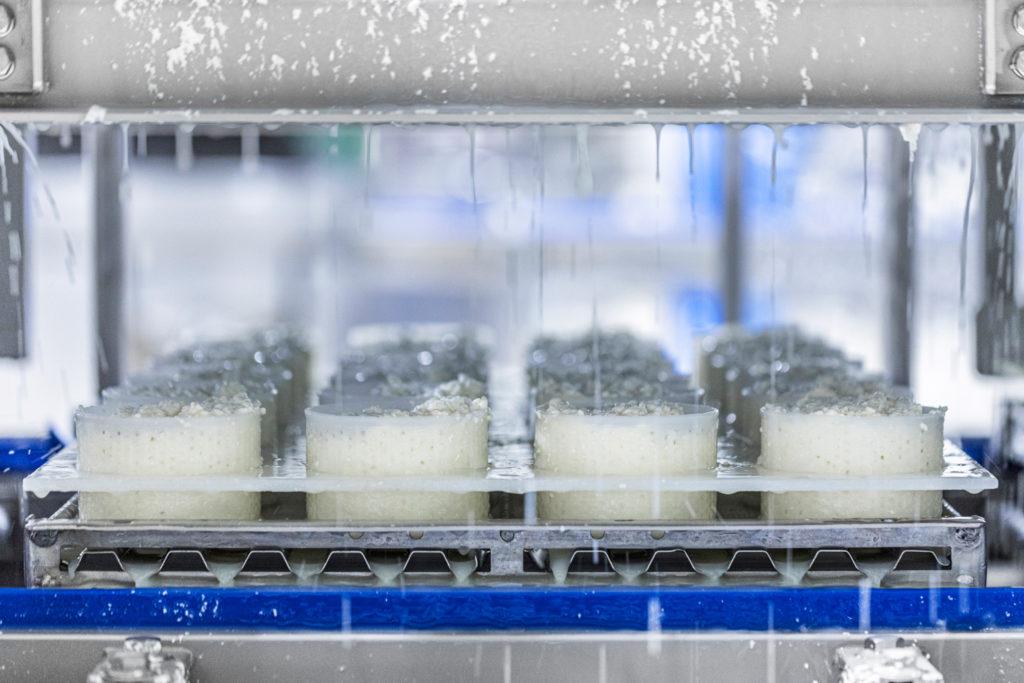

7. Turning and demolding: During the cheese stabilization period, cheeses are turned to ensure a uniform shape and consistent texture in the product. At FIBOSA we offer solutions to optimize this stage such as the Multimold Turner.

8. Salting: The salting process, either by immersion in brine or dry salting, enhances flavor and acts as a natural preservative.

9. Ripening: Although fresh cheese does not require prolonged ripening, it can undergo a brief period of resting in chambers to develop the desired organoleptic characteristics.

10. Packaging: We pack fresh cheese with systems that guarantee hygiene and prolong the shelf life of the product, to preserve its freshness and quality.

FIBOSA: Technological solutions for fresh cheese production

At FIBOSA we understand the importance of offering the market a fresh cheese that meets the strictest quality standards. Therefore, we develop machinery designed to optimize each stage of the production process, integrating state-of-the-art technology that ensures efficiency, hygiene and sustainability.

Our solutions include:

- Automatic pasteurizers: with equipment that guarantees homogeneous and efficient pasteurization, preserving the nutritional and organoleptic properties of the milk.

- Coagulation and cutting equipment: to maximize curd yield and minimize whey losses.

- Flexible molding systems: adaptable to a wide variety of formats and production needs.

- Sanitized packaging lines: with advanced technology that ensures the freshness and safety of the final product.

Our technology allows producers to achieve higher levels of productivity, guaranteeing a final product that meets consumer expectations.

At FIBOSA, we are always at the forefront, incorporating the latest technological innovations to make production processes more efficient and profitable. We focus on creating customized solutions, adapting our equipment to the specific needs of each customer.