The innovation the dairy market has been waiting for

The global mozzarella market is experiencing unprecedented growth, with demand for this popular Italian cheese growing steadily in the United States, Europe and Asia. Unlike other cheeses, mozzarella requires a specific spinning process that gives it its characteristic elastic texture, which required specialized machinery for its production that until now was scarce in the market. In this context of expansion, the objective of FIBOSA‘ s R&D&I department has been to offer an efficient, adaptable and automated solution for the production of mozzarella.

Fibosa officially announces its new mozzarella production line

After months of technical analysis and market research, we are proud to present our first industrial machinery lines specifically designed for the production of mozzarella cheese.

The mozzarella cheese making process perfected step by step

The specific process of mozzarella – with its characteristic spinning phase, elastic texture and precise maturation times – implies unique technical requirements that Fibosa ‘s new line masters to perfection:

Initial processing vat: The milk enters the vat where the heating system brings it to the exact required temperature. Rennet and ferments are added, stirring until the perfect curd is obtained.

Draining and controlled maturation: The rennet is drained and transferred to specialized carts where it rests until it reaches the exact pH, a fundamental parameter for the creation of mozzarella.

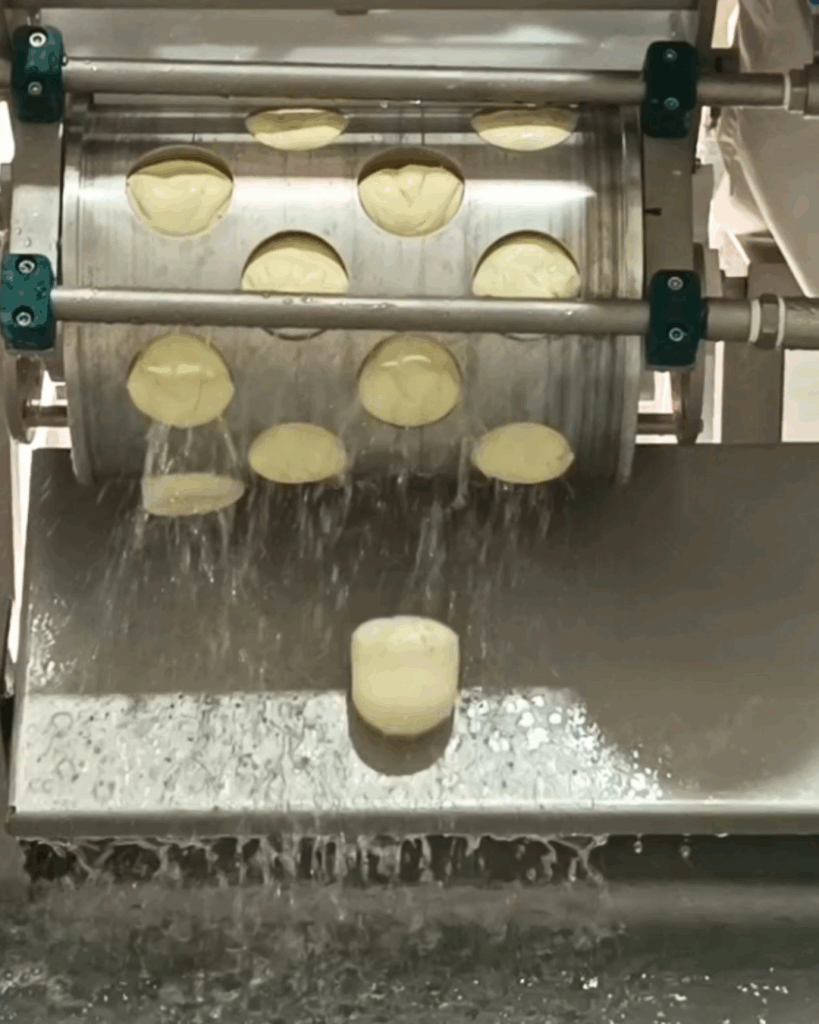

The spinning machine: The blocks are transferred to the spinning machine, where they are heated with steam until the perfect elastic texture is achieved. Brine is added and sent to the molding area to start creating the mozzarella balls.

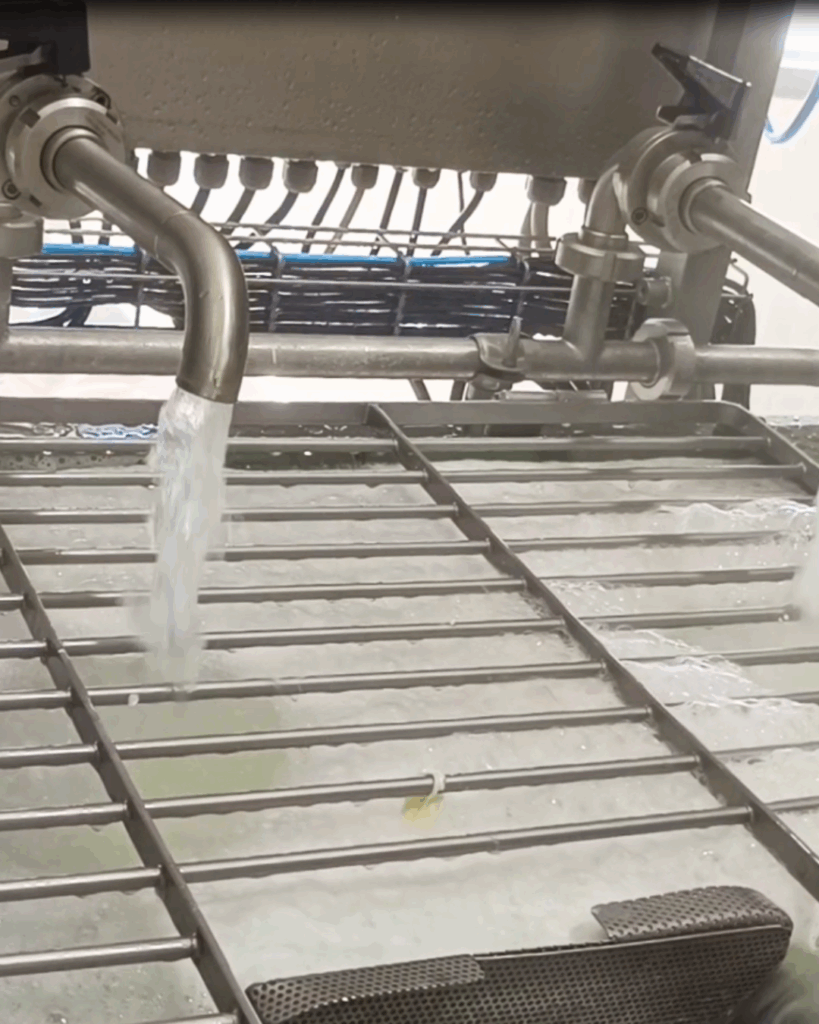

Precise cooling: Once the balls are formed, they fall into the cold water tank where they are cooled to the exact temperature at the core of the mozzarella ball. This temperature change generates the final texture transformation.

Packing with liquid packing: Once the mozzarella portion is finished, it is sent to the packing machine where it is packed in bags with liquid packing for optimal preservation of the cheese until it is consumed. This governing liquid guarantees that the salt concentration of the mozzarella is always perfect and does not change.

The perfect time for mozzarella production

The numbers speak for themselves: according to data from SkyQuest Technology, the global mozzarella market reached $42.3 billion in 2023 and is projected to grow to $77.12 billion by 2032, at a CAGR of 6.9%. This exponential growth is driven by the popularity of pizza, the expansion of Italian food worldwide and the rise of ready meals.

According to Research and Markets, the sector is experiencing a compound annual growth rate of 6.3%, with a particular focus on key markets such as the United States, Europe and Asia, where consumers are looking for versatile, healthy and foodservice-friendly dairy products.

For those responsible for production, purchasing and management of dairy companies, this trend represents a great opportunity. Fibosa’s new line not only makes it possible to take advantage of this global boom, but also to do so with the efficiency and quality demanded by an increasingly competitive market.

Efficiency, adaptability and automation

Fibosa’s proposal goes beyond machinery: it is a comprehensive solution that combines:

- Complete automation of the process, reducing labor costs, human error and preserving hygiene throughout the process.

- Adaptability to different production volumes and product specifications.

- Energy efficiency with optimized heating and cooling systems.

- Integrated quality control at each stage of the process.

- Ease of maintenance with modular design and simplified access.

The future of dairy production with Fibosa

With this new line, Fibosa not only responds to a market demand, but also sets a new standard in mozzarella production. For dairy companies seeking to diversify their offer or optimize their existing production, this technology represents an opportunity to position themselves as leaders in a high-growth segment.

The mozzarella revolution has begun, and Fibosa is leading the way with innovation, expertise and a clear vision for the future of the dairy industry.

For more information on how Fibosa’ s new line of mozzarella machinery can transform your production, contact our sales team.