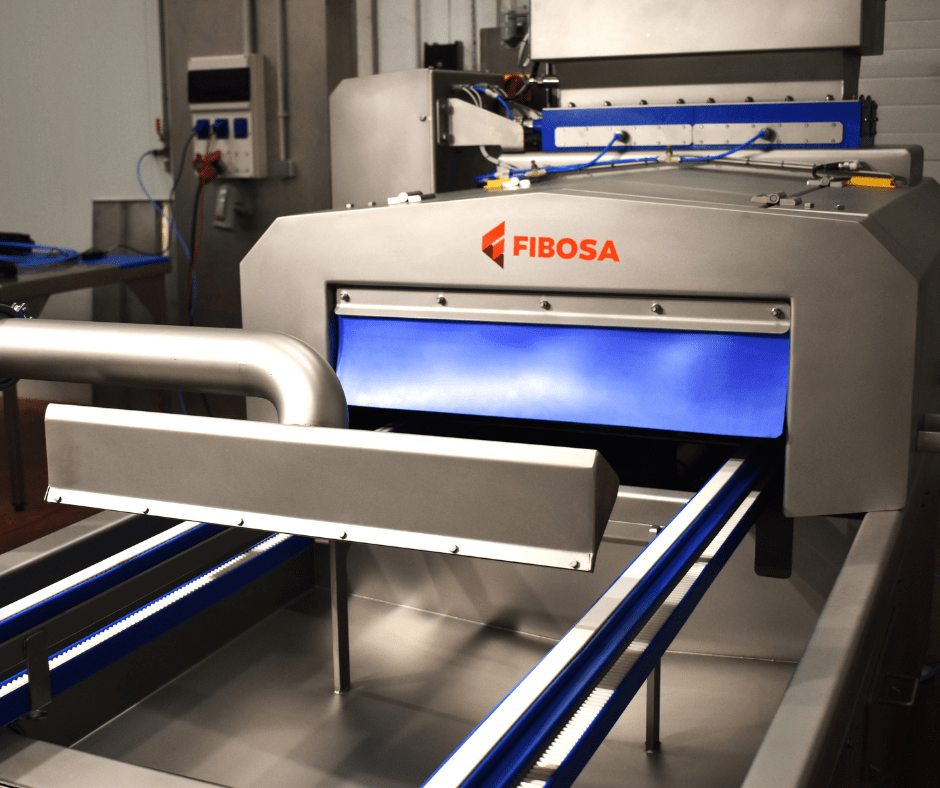

The continuous salting tunnel for fresh cheese is an automated solution designed to optimize the salting process in the cheese industry. Its advanced technology improves efficiency, uniformity and hygiene, surpassing traditional methods such as the use of static tanks.

How does the continuous salting tunnel work?

1. Integration after molding and self-pressing

This advanced system is implemented after the molding and self-pressing of soft cheeses, ensuring a smooth transition in the production process.

2. Transport on ripening grids

The cheeses are introduced into the tunnel using the same grid used for ripening. This reduces logistical costs and improves hygiene by eliminating the need for additional manual handling.

3. “Curtain-type” salt distribution system

The tunnel is equipped with a dry salting mechanism by means of a “curtain-type” salt distribution system located at the top. This system guarantees a homogeneous coverage on the upper surface of the cheeses.

4. Uniform salt application with lower nozzles

In the lower part, a system of nozzles diffuses air that applies salt uniformly on the base of the cheeses, ensuring a balanced salting on all sides.

Continuous salt tunnel applications

The system is designed to optimize the salting process in several varieties of fresh and soft cheeses, including:

- Fresh cheeses: feta, Burgos, panela, among others.

- Soft cheeses: Brie, Camembert.

The main objective is to achieve homogeneous salting, controlling humidity and improving texture and flavor.

Advantages of the continuous salting tunnel vs. traditional methods

The continuous salting tunnel offers greater efficiency by reducing labor and speeding up the process, unlike the traditional method, which requires constant supervision. It ensures greater uniformity thanks to its system of nozzles and salt curtain, avoiding batch-to-batch variability. It also reduces operating costs by minimizing handling and the risk of damage to the cheese. Its hygienic design limits manual contact and facilitates cleaning. It also optimizes salt consumption, with less brine use and more sustainable dry salting. Finally, the tunnel is easily integrated into automated cheese manufacturing lines.

| Appearance | Continuous salting tunnel | Traditional method (brine salting basins) |

|---|---|---|

| Efficiency | Faster process. Reduces labor. | Slow process with manual supervision. |

| Uniformity | Homogeneous salting with “curtain type” system and nozzles. | Variability between batches or pieces. |

| Operating costs | Savings due to the use of maturation grids. | More handling and risk of damage to the cheese. |

| Hygiene | Less manual contact, easy cleaning. | Increased risk of contamination. |

| Salt consumption | Requires low energy consumption. | The use of brine requires the use of filters, a pumping system and a brine cooling system, which entails high energy consumption. |

| Automation | Adaptable to automated lines: integration in industrial processes. | As it is not a continuous process, it is difficult to integrate into automated processes. |

Impact on the cheese industry

At FIBOSA, we design cutting-edge solutions for the cheese industry, helping our customers to improve their efficiency, quality and sustainability. Our continuous salting tunnel for fresh cheese is the result of our experience in automation and industrial processes, offering producers a reliable and efficient tool to optimize their production.

Want to know more? Contact us to find out how we can help you modernize your fresh cheese production line.