Process automation in the food industry is not just a trend, but a necessity to optimize time, reduce human error and ensure traceability. In this context, automatic cheese depalletizing is a key solution for cheese production plants seeking to improve efficiency without compromising product quality.

Robotized cheese depalletizing and case packing

FIBOSA’s advanced systems allow an integral management of cheese, integrating robotics to cover all the phases of the process. Below, we detail each one of them:

1. System preparation

Before starting the process, the system loads all the elements necessary for its operation:

- Pallets with stacked boxes.

- Previously packaged cheeses.

- Packaging materials.

This initial step ensures an uninterrupted flow in the following stages of the automated process.

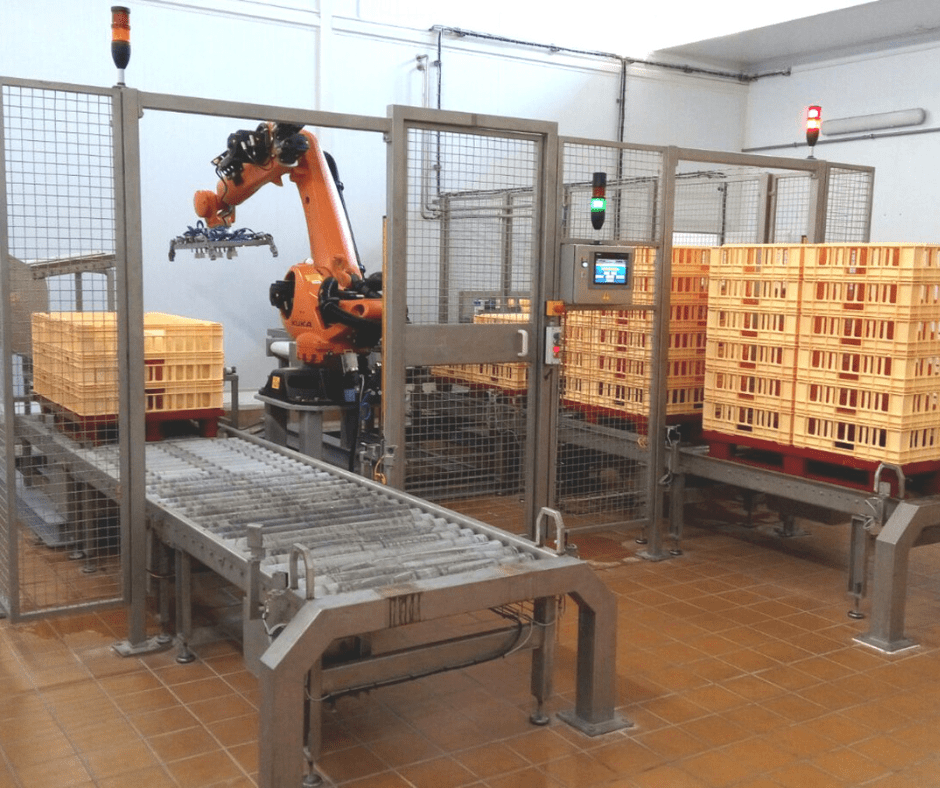

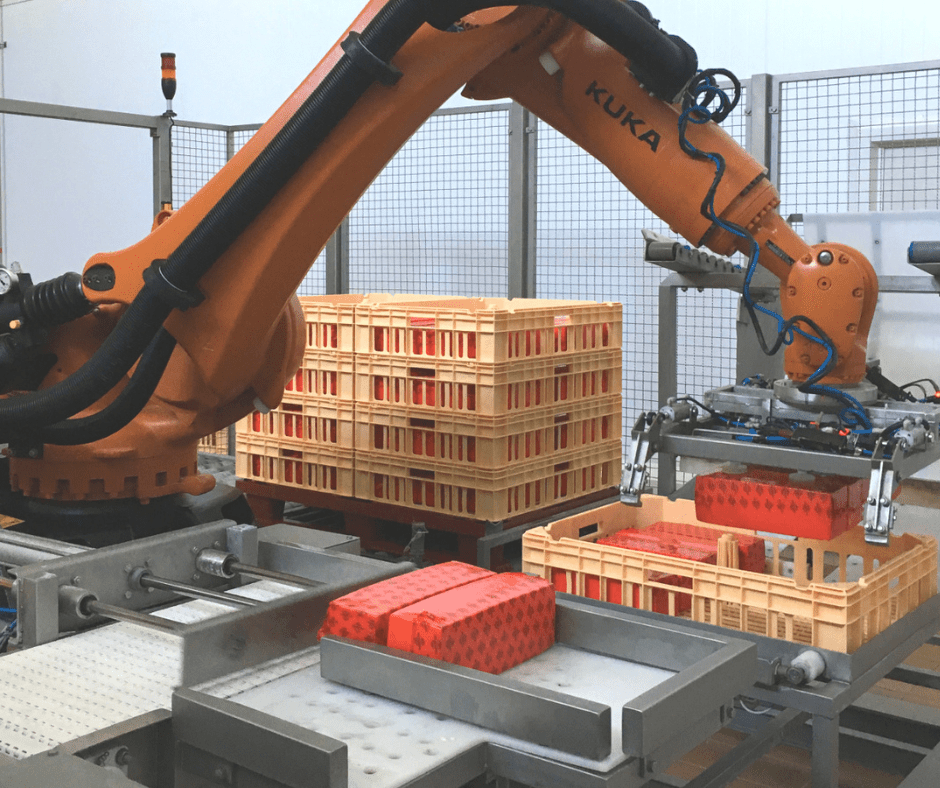

Depalletizing and extraction system for packaged cheeses

Product origin

The packaged cheese comes from plastic crates stacked on pallets. This allows an orderly and optimized handling for automatic depalletizing.

System operation

A depalletizing robot carefully removes the packaged cheeses from each box. This process is carried out using a system that preserves the integrity of the product.

- Empty crates or empty pallets are automatically transferred to your cleaning or storage circuit.

- The packaged cheese is deposited on a conveyor belt for subsequent quality control.

In addition to automating the process, this system also guarantees hygienic treatment of the product.

3. Quality Control

Once on the belt, the cheese undergoes a strict quality control:

- Visual inspection by cameras, capable of detecting external defects, inconsistencies or non-conforming products.

- Automatic weighing to verify that each unit complies with established standards.

- Automated labeling, which ensures traceability and identification of each piece before final packaging in cartons.

4. Cheese packaging

Once quality control has been passed, the system proceeds to the packaging phase:

- A robot places the cheese in open cartons.

- The boxes are then automatically closed and labeled for subsequent marketing.

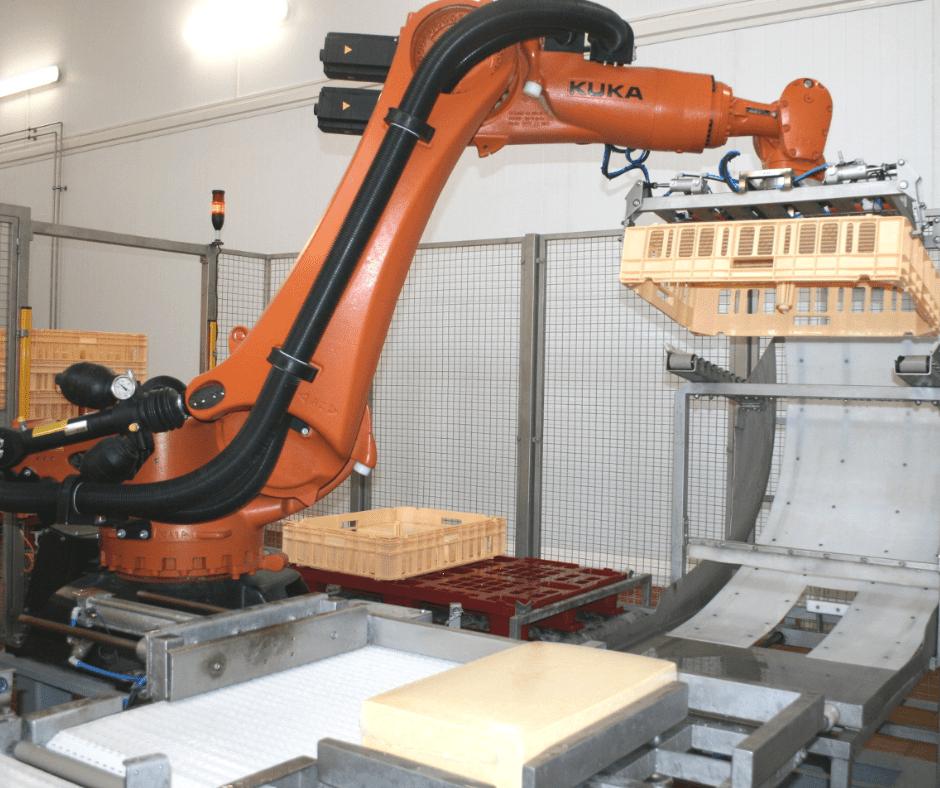

5. Automatic palletizing

The process concludes with automatic palletizing, adapted to two formats depending on the destination of the product:

- The robot arranges the filled boxes on the pallet according to a predefined pattern.

- Cardboard sheets are sandwiched between layers to stabilize the load.

- The pallet is labeled and moved to the shipping or storage area.

Cheeses in plastic crates on plastic pallets

- The robot places the cheeses in plastic boxes.

- The boxes are stacked securely on the pallet.

- The pallet is labeled and ready for evacuation or internal logistics.

6. Fully automatic and secure system

The entire system is designed to operate fully automatically, minimizing human intervention. This has significant advantages for the industrial environment:

- Reduced occupational risk by eliminating repetitive or heavy tasks.

- Increased operational efficiency by avoiding downtime and human error.

- High safety standards, both for the operators and for the food product.

Automatic cheese depalletizing is much more than a technical improvement; it is a strategic tool for companies seeking competitiveness, hygiene and productivity in a highly regulated industrial environment. At FIBOSA we design and manufacture tailor-made solutions that optimize each stage of the process with maximum reliability, hygiene and performance.

Want to learn more about how to automate your cheese production plant?

Contact FIBOSA to discover how we can help you transform your production line.