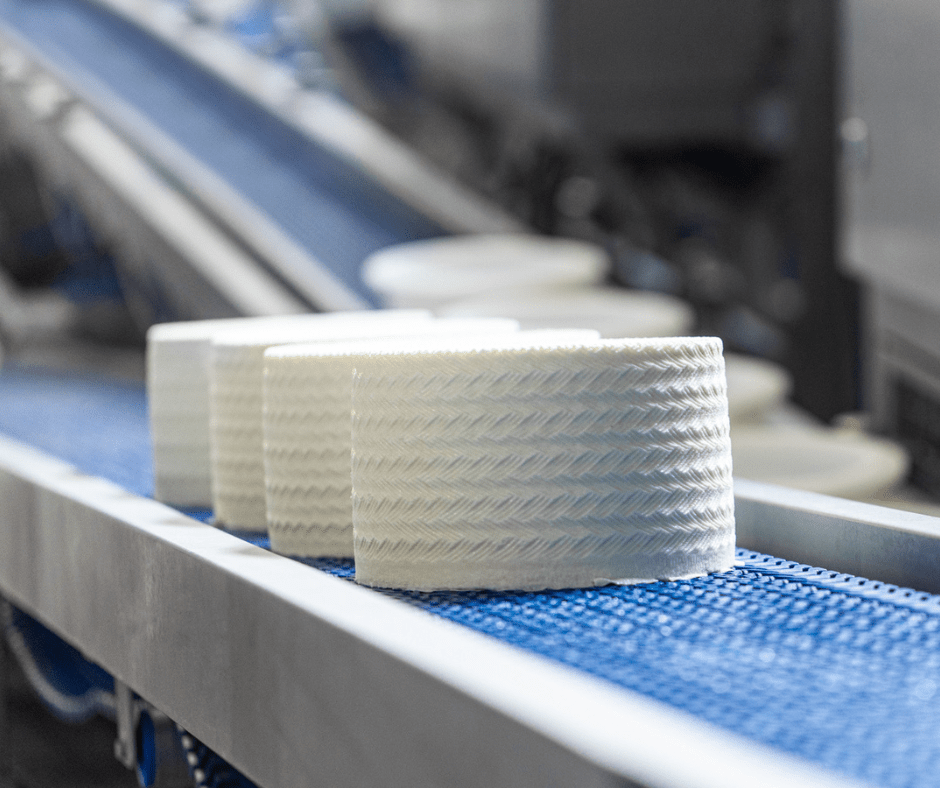

In today’s cheese industry, it is essential to have solutions capable of producing a wide variety of cheeses, with different formats and textures, without sacrificing efficiency or quality. The demand for more flexible, automated and efficient systems continues to grow, and responds to the need to remain competitive in an increasingly dynamic industry. In this context, a cheese dosing system is essential to optimize the production process. A clear example of this solution is the Fibosa’s DOSIMATIC universal dosing machine, a machine designed to provide precision, accuracy and reliability a machine designed to provide precision, versatility and performance at every stage of production.

Why choose a universal dosing machine?

The need for flexible and efficient solutions in cheese production

In today’s industrial context, production lines must adapt quickly to different types and formats of cheese, without affecting quality or production volumes. This is where Fibosa’s DOSIMATIC universal cheese dosing machine becomes a strategic ally for large producers.

These machines integrate in a single unit the dosing, compacting and molding systems, allowing the production of open or closed paste cheeses, and of different consistencies: semi-hard, hard and cagliata. In addition, its compact design helps to optimize the available space and reduces manual handling, thus increasing efficiency and ensuring excellent homogeneity in the final product. All this with the possibility of customizing the equipment according to the specific needs of each customer.

Among its main advantages are the following:

- A single equipment, multiple types and formats of cheese in the same production line.

- Curd distributor with agitation and filtering systems.

- Efficient disposal process.

- Exclusive design micro-perforated columns.

- Different levels of water extraction to adapt to each type of product.

- Interchangeable and automatically adjustable formers.

Fibosa’s Universal Dispenser: an innovative and versatile solution

Optimizing large-scale cheese production requires technology that is easily adaptable to different products and formats. Fibosa’ s Universal Doser has been designed precisely for that purpose: to offer a versatile, efficient and easy-to-integrate solution for any modern production line.

Thanks to its compact and multifunctional design, it allows working with different varieties of cheese – from open to closed paste, and from soft to hard textures – in a single machine. This translates into higher productivity, less handling and consistent quality in the final product.

Here are three key aspects that make this machine a particularly competitive option for industrial cheese producers.

Automation and intelligent process control

One of the main advantages is its automation capability. It incorporates a programmable automaton and an intuitive touch screen, which facilitates its daily use and allows precise control at every stage of the process.

This system allows, among other functions, to automatically regulate the whey level according to the type of cheese being produced. This achieves greater uniformity in the final product, while optimizing production parameters without the need for constant manual adjustments.

Hygiene and maintenance designed for daily use

In the food industry, maintaining high hygiene standards is essential. That is why the DOSIMATIC universal cheese dosing machine is designed with an enclosed structure that allows efficient and safe CIP (Clean In Place) cleaning without the need for complicated disassembly.

In addition, the equipment incorporates practical solutions for maintenance, such as a hoist to extract the columns, an access platform to perform tasks safely and comfortably, and the option of integrating a specific washing cabinet for the columns and accessories. Everything is designed to speed up day-to-day tasks, minimize downtime and always guarantee the required hygienic conditions.

Versatility, efficiency and sustainability: key benefits

The main value provided by this technology is its high versatility. With a single machine, producers can produce multiple types of cheese, allowing diversification of the product range without the need to expand facilities or incorporate additional equipment.

In addition, its compact design and multifunctional capabilities help to reduce space requirements and manual handling, resulting in lower operating costs and improved ergonomics for personnel. At the same time, productivity is increased and consistent quality is maintained, meeting market standards.

Another plus point is its sustainable approach. The possibility of recovering the whey during the process helps reduce waste and promotes a more efficient use of resources, an advantage increasingly valued by the industry.

Finally, Fibosa’ s Universal Dispenser adapts to every customer and every production need. It is a strategic choice for companies that want to grow by relying on reliable, flexible technology that is ready to face the challenges of the future.

If you are looking for an innovative and versatile solution to improve your cheese production line, contact FIBOSA and find out how we can help you take the next step.