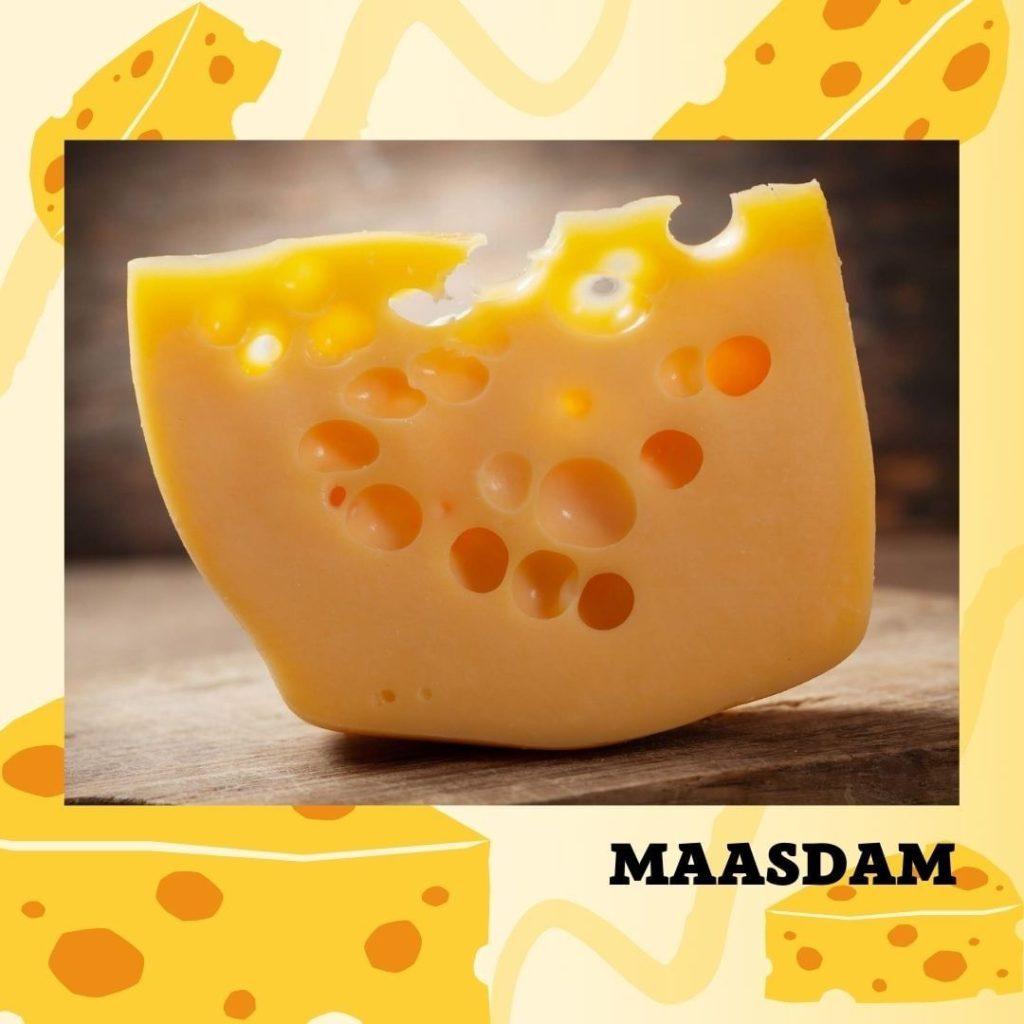

Maasdam cheese, originally from Holland, is much more than a simple cheese: it is a delicacy that stands out for its creamy texture and its characteristic holes. Produced from pasteurized cow’s milk, this semi-hard cheese has sweet and fruity notes in its flavor. What many do not know is that, behind every piece of Maasdam, there is advanced technology and specialized machinery that make its characteristic elaboration possible.

An interesting fact is that Maasdam is named after the village where it was born, reflecting the rich cheese-making tradition of the region. Today, Maasdam makes up about 15% of the total cheese production in the Netherlands, demonstrating its immense popularity not only locally, but also internationally.

To achieve the consistency, flavor and characteristic holes of this cheese, state-of-the-art machinery is essential. At FIBOSA, we are one of the leading companies in this field. We are specialized in designing complete plants and production lines for the dairy industry. From the reception of raw milk to the packaging of the final product, Fibosa offers comprehensive solutions that guarantee the quality and authenticity of Maasdam.

The formation of the characteristic holes in Maasdam cheese, for example, is the result of controlled fermentation processes that require tanks and optimal temperature and humidity conditions. Our machinery ensures that these conditions remain constant, allowing the cheese to mature properly and acquire its distinctive flavor and texture.

In short, behind every delicious bite of Maasdam cheese, there is a perfect synergy between tradition and modern technology. The advanced machinery offered by Fibosa ensures that cheese lovers around the world can enjoy the authentic Maasdam experience, with all its unique characteristics and unmistakable flavor. A tribute to innovation in the dairy world!

Contact FIBOSA, we are at your disposal to solve any doubt or question you may have.