Cheese production has found in modern technology an essential ally to meet today’s market demands. Today, it is not only a matter of producing more, but also of producing better: with precision, speed and maintaining high quality standards. In this context, cheese pressing and demolding systems play a fundamental role.

At FIBOSA, leaders in pressing and demolding solutions, we develop state-of-the-art technologies to optimize these processes, guaranteeing our commitment to quality and innovation in cheese production.

Continuous cheese pressing systems

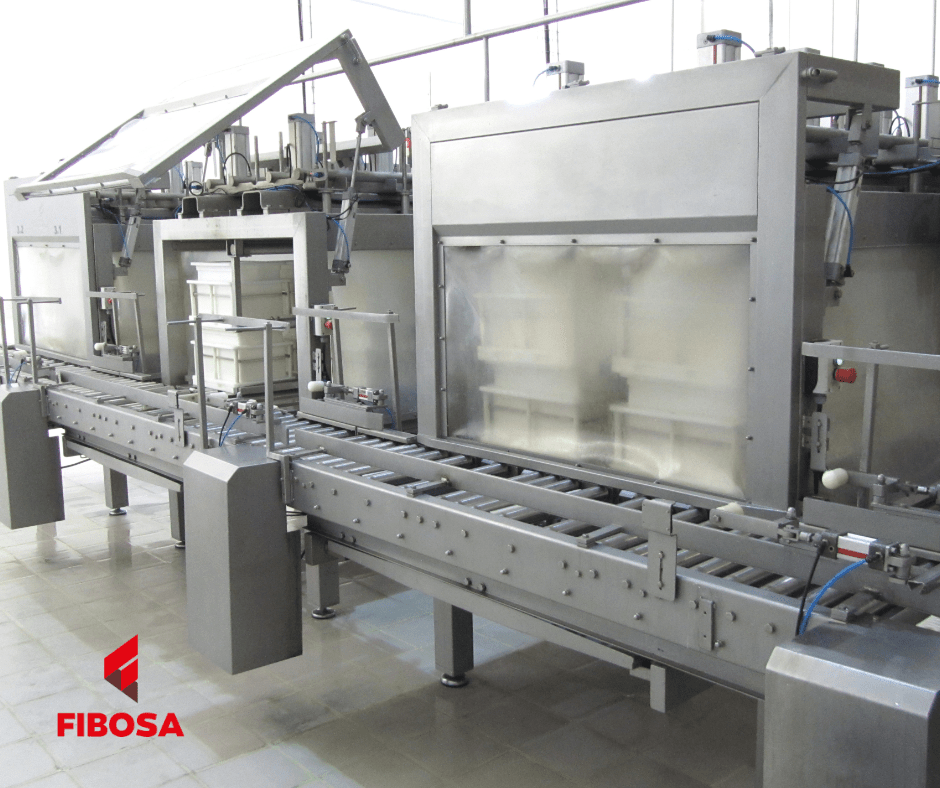

FIBOSA’s PRENSAMATIC presses have been developed for continuous cheese pressing. Our pneumatic cushion pressing system is characterized by distributing the pressure evenly in all the molds regardless of their shape and size and also through the adaptability of the cushion, uniformity of pressing is achieved, even if there are small differences in curd height.

Our presses are equipped with automatic loading and unloading, trays and whey collection tank, adapted for CIP cleaning. It also includes washing of the conveyor belt and mattress by means of a set of strategically placed sprinklers that achieve an integral washing.

All PRENSAMATIC functions are controlled by a PLC control panel with touch screen.

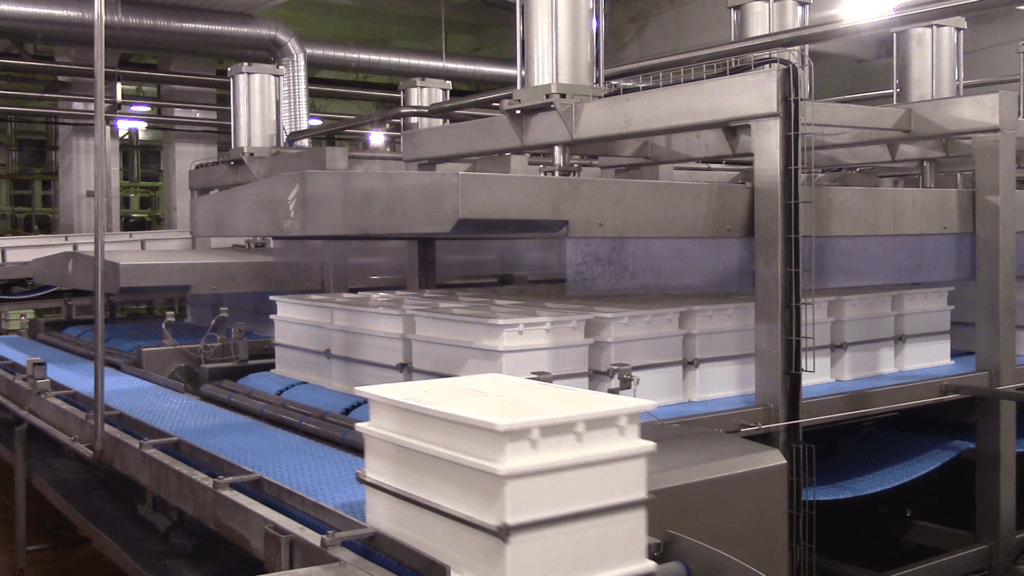

Manufacturing of loading and unloading presses

In order to offer solutions adapted to each type of production, we also manufacture single cylinder automatic loading and unloading presses, designed for the continuous pressing of large molds. In addition, we have a wide range of horizontal and vertical presses with manual loading and unloading, ideal for medium and small productions, providing our customers with the necessary flexibility to adjust to the specific demands of their production.

Demolding systems

DESMATIC equipment automatically extracts the cheese from the mold by means of a controlled discharge of pressurized air with enveloping hoods adapted to the shape of each mold. This equipment stands out for its ease of format changeover and its integration with a conveyor belt and a control panel that automate the process.

In addition, FIBOSA produces semi-automatic demolding machines for cheese demolding with manual loading and unloading for artisan productions.

Advantages of pressing and demolding systems

Cheese pressing and demolding systems stand out for their efficiency, quality and adaptability. These solutions not only improve productivity, but also guarantee a high quality end product.

With our innovative approach and commitment to efficiency, FIBOSA continues to be a benchmark in the cheese industry.